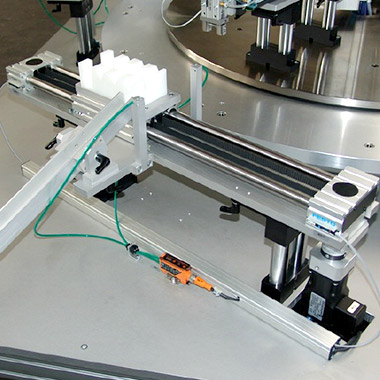

The system is supplied with parts via a feed chute and these are fed either manually or via a loading system. The width of the chute can be adjusted via a detachable partition wall, in order to accommodate short and long components. The sleeves to be processed are attached to the workpiece holder thorn pneumatically.

In the subsequent alignment station, a pincer turns the sleeves into the correct printing position. The sleeve is held on the thorn pneumatically prior to the actual printing process. Once the printing process has ended, the workpiece is dried using hot air and then placed in the pick-up position by the pincer or offloaded onto a tray by a robot.

The system is controlled via a control panel which is attached to a swivel arm and allows for a pivot angle of approx. 270° around the system. This prevents it from entering the loading and offloading areas.

Our solution

The TAMPONCOLOR TC 60-80 T-RT/Servo printing system provides customers with a complete solution for their print applications – one which is uniquely tailored to their needs. The construction of the machine is developed in cooperation, ensuring that operating personnel are met with familiar components and structures. This minimises training, set-up and maintenance costs, allowing the system to be integrated into production with hardly any delay.