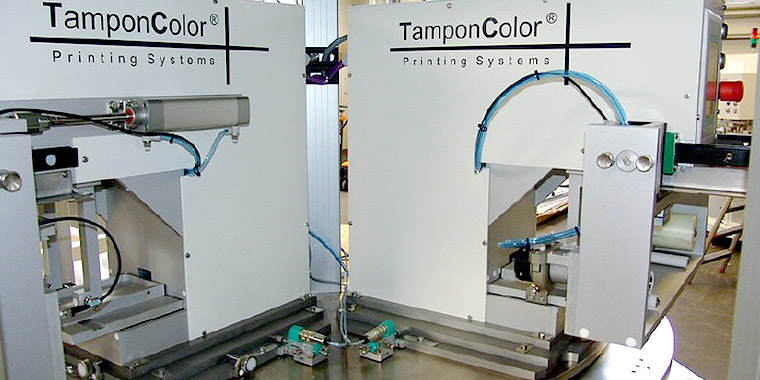

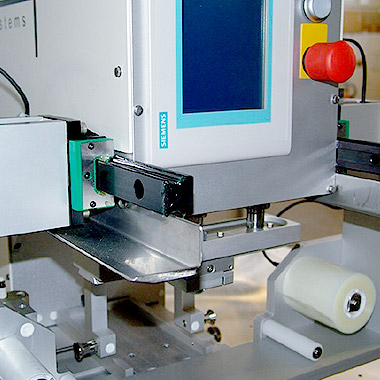

Pad printing machines for the pharmaceutical industry

Round pieces of plastic are to be printed with a two-colour scale. As well as boasting a high hourly output with 2,100 cycles, the repeat precision of the pad stroke is also crucial for a consistently precise printed image. The print heads are built into a manufacturing cell which is adapted in terms of materials and design to meet the requirements of the final customer and which will later be equipped with additional handling equipment.