Pad printing systems

Pad printing machines that can do more

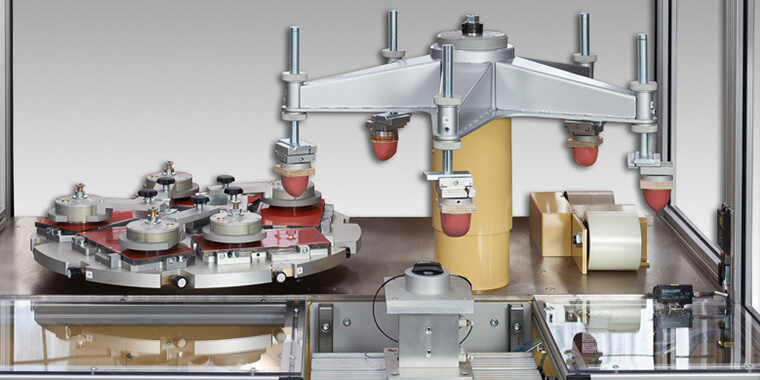

Pad printing systems are based on pad printing, an indirect gravure printing process that is characterized in particular by its wide range of possible applications combined with high print quality. One or more of the elastic tampons made of silicone rubber, which give the system its name, transfer the printing ink from the cliché to the object to be printed. The material of the object does not play a major role: while plastics are probably the most commonly printed materials in pad printing, paper, wood and even glass and metallic surfaces can also be printed. Thanks to the adaptability of the pad, surfaces of almost any shape can be decorated in outstanding quality.

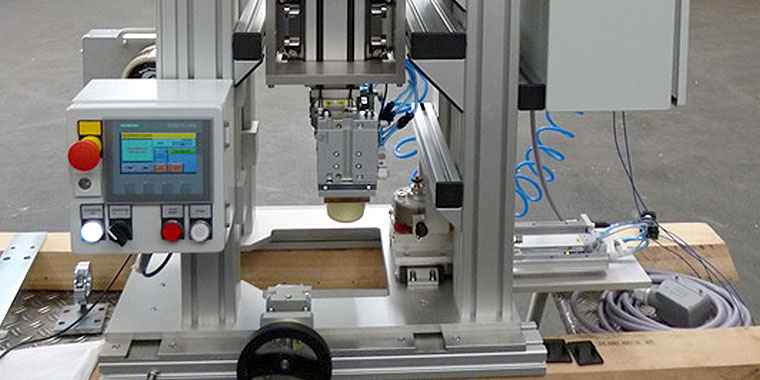

Our pad printing systems offer the right solution for every requirement. High-precision multicolor printing with 1 to 5 colors with manual or variable fully automatic feeding is possible, as is the integration of a pad printing system into injection molding processes, which makes subsequent handling steps unnecessary for single-color decoration. Modular design also allows printing systems to be configured according to customer requirements, where not only the ink systems but also the method of part transport can be freely selected. This facilitates integration into existing processes.

If required, a servo-electric 3-axis system ensures highly accurate single and multi-color printing with arbitrarily positioned print images – thanks to 300 storable programs, this is also extremely flexible for small and medium-sized batches.

Tamponcolor pad printing systems are versatile, with typical print products ranging from fittings to promotional items, from medical products to ballpoint pens.